Tips on Metal Matrix Composites

(MMC)

What is Casting?

Casting is a manufacturing process by which a liquid metal (molten metal,

melt) is usually poured into a mold, which contains a

hollow cavity of the desired shape, and then allowed to solidify. The metal

product made by this process is also known as a casting. Casting is often used

for making the products with complex shapes that would be otherwise difficult

or uneconomical to make by other methods.

What is Metal Matrix Composite?

Composite is

the materials fabricated by mixing the different starting materials. The

composite has properties superior to the monolithic material. The composites

with plastic matrix, with metal and with ceramics are called plastic matrix

composite, metal

matrix composite, and ceramics matrix composite, respectively. Many of the plastic matrix composite are the ones which contain the fibrous

carbon or glass in the plastics (resin).

They are called fiber reinforced plastics (FRP). Metal matrix composites

are generally applied for the use at elevated temperature.

Industrial application of Metal Matrix Composite

Ceramics

particle- dispersed aluminum alloy composites are used for some of brake discs

which requires wear resistance, exothermic and friction force. Replacing the

cast iron disc with the composite contributes the weight reduction of the part,

preserving its performance.

Ceramics fiber-reinforced aluminum alloy composites are used for some of

engine parts, such as piston, cylinder block and connecting rod, which requires

high temperature strength and wear resistance.

Composite

casting technology

Practical application of metal matrix composite is outstripped by FRP due to

the difficulty of the fabrication. Solid phase process such as powder

metallurgy, diffusion bonding, HIP are expensive because it needs expensive

starting materials such as powder or foil matrix, and it has many manufacturing

process. Liquid phase process (casting process) is generally less expensive

than solid phase process. In the

casting process, high temperature melt is used. High temperature often promotes

the chemical reaction between the melt and the reinforcements. The reaction

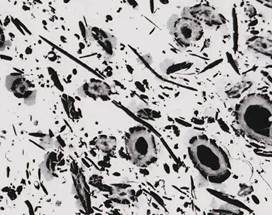

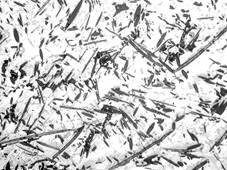

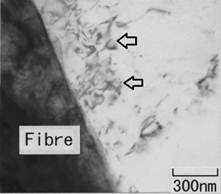

leads to the degradation or disappear of the reinforcements. The typical

example of the reaction is shown in Fig.1. The expected properties of

the composite wouldn乫t be obtained if this reaction occurs. Generally, the

wettability between the melt and ceramics is bad, so special techniques would

be required when you want to obtain the metal matrix composite in which small

ceramic particles or whiskers are homogeneously dispersed into the matrix.

Needless to say, examination of their microstructure is very important to

conjecture their properties.

|

|

Fig. 1丂New phase (gray)

formed by the reaction between ceramics fibers (black) and magnesium

alloy(white) in the composite fabricated by squeeze casting.

This section gives an outline of each

casting technology to fabricate the composites.

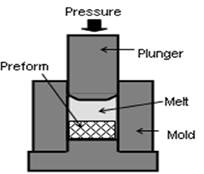

Figure 2 shows a

schematic illustration of the squeeze casting.

Ceramic fiber or particle preform is

placed in the permanent mold, then the melt is poured

into the mold, followed by applying the high pressure using a plunger while the

melt solidifies. The preform consists of the reinforcement and cavity, and the

cavity allows the melt to infiltrate into the preform. By forging the melt, the

melt infiltration into the preform can be achieved even though the wettability

between the melt and the reinforcement is poor. In addition, near net shape

with high process speed can be achieved in sound, fully dense castings.

Fiber-reinforced aluminum alloy composites produced by the squeeze casting are

applied to the parts, such as automobile engines, conveyor rollers for carrying

cokes and coals, etc. The melt infiltration with lower pressure (ex. gas

pressure) can be accomplished by increasing the size of reinforcement and mixing

the metal powder in the preform. Vacuum assist casting is a melt infiltration

process using the suction by the reduced pressure. Centrifugal casting is a

technique using the centrifugal force in the cylindrical mold to infiltrate the

melt into the reinforcement preform or to disperse the reinforcement

outside or inside of the castings by the difference in specific gravity.

Spontaneous

infiltration is a melt infiltration process without pressure. Although this

process is the simplest and most advantageous in cost, it is necessary to use

the special agent (powder in the preform, atmosphere gas, etc)

to accomplish the infiltration because the wettability between the melt and

ceramics are generally not good. The thermit

reaction between the agent and melt promotes the infiltration. Famous example

of this technique is the Lanxide process (PRIMEX

process TM, DIMOX process TM) .

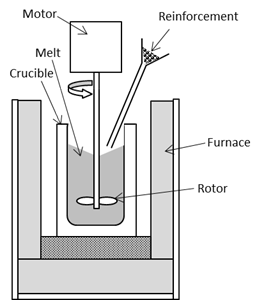

Vortex

method is a technique involving the melt stirring to disperse the reinforcement

(particle or whisker) in the matrix. Propeller as illustrated in Fig.3 or electromagnetic force is used

to stir the melt. Famous development example of the composite by this technique

is DuralcanTM , which SiC

or Al2O3 particles are dispersed in aluminum alloy. Compocasting is same technique as the vortex method, except

for stirring at the temperature that the matrix consists of solid and liquid.

Because the wettability between the melt and ceramics are not good, the

wettability must be improved to disperse the reinforcement homogeneously by

these techniques. Addition of alloying elements and metal coating on the

reinforcement have been attempted to improve the wettability.

In situ process is a technique to

synthesize the reinforcement by the reaction between the melt and the additives

or atmosphere. The synthesized reinforcement is thermodynamically stable in the

melt; the strong bond between the matrix and the reinforcement can be obtained.

Cast-in

insertion is a technique to join the different materials by pouring the melt

into the mold in which the bulk material (reinforcement) is placed. Although

the difference with the infiltration process is sometimes unclear, we think

that the reinforcement size is relatively large and its macroscopic shape and dimension

is functionally significant for the cast-in insertion.

Simultaneous

pouring is a technique to obtain the structural gradient in the castings by

pouring several kinds of the melt in a mold. Cast iron and aluminum alloy

castings are fabricated by this technique.

Each technology listed in this section

is independently used or combined. The materials and shape of the matrix and

reinforcement are selected considering applied properties, cost, wettability,

bond strength, etc.

|

|

|

|

Fig. 2 Schematic

illustration of the squeeze casting.

|

|

Fig.3 Vortex method

Examination of microstructure of metal matrix composite

Measurement of reinforcement volume fraction in composite

For squeeze casting, the melt infiltration into the preform might cause

the contraction and deformation the preform when the preform strength is not

enough. For voltex method, some of the added

reinforcement into the melt would be ejected due to the bad wettability between

the melt and the reinforcement. These things lead to the difference between the

expected and obtained volume fraction of the reinforcement in the composite.

Therefore, the volume fraction in the composite must be exactly measured.

Analyzing of the micrograph of the composite with image analyzer is one of

method to measure the volume fraction. The area fraction of the reinforcement

can be converted to the volume fraction.

Most popular method would be Archimedean method. Density of the composite

can be measured from the buoyancy in a liquid using the Archimedes乫 principle.

Accurate value can be easily obtained by this method if the density of matrix

and the reinforcement is known.

Porosities or defects must be avoided to obtain the accurate value.

Observation of microstructure

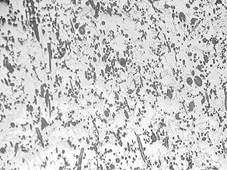

Optical and scanning electron micrograph are

used to observe the dispersion of the reinforcements in the composite. Figure

4 shows the optical micrographs of the short alumina fiber reinforced

aluminum alloy composite fabricated by squeeze casting. Long fibers can be

observed in the microstructure parallel to the pressed plane (Fig.4(a)), while

sections of the fiber can be observed in the microstructure perpendicular to the pressed plane

(Fig.4(b)) ; the

nearly planar random nature of the fiber orientation can be clearly seen. In

many cases, the fiber distribution in the composite is inherited from the

preform.

|

(a) Parallel to pressed plane |

(b) Perpendicular to pressed plane |

Fig.4 Optical micrographs of short alumina fiber reinforced aluminum alloy composite

fabricated by squeeze casting (fiber volume fraction; 15vol%).

Bundle, plain

or satin fiber are used as the reinforcements for continuous fiber reinforced

composites. Squeeze casting is often used to fabricate this composite. For the unidirectionally reinforced composite, the

fiber contact is often shown caused by the contraction of the preform during

melt infiltration. The stress concentrates at the points of

direct fiber contact, and stress transmission between the fiber and the matrix

becomes difficult. To prevent the fiber contact, dispersion of fine particles

or whiskers between the fibers in the composite using a preform of the fibers

having particles or whiskers attached to their surfaces has been proposed. The

composite is called a hybrid composite.

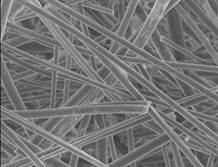

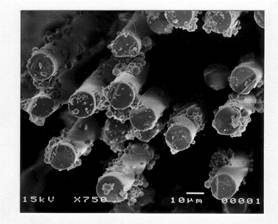

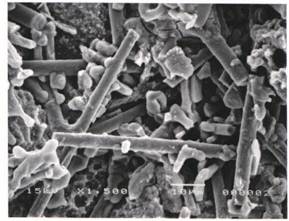

Figure 5 shows a SEM image of a preform to fabricate the hybrid

composite. The particles can be seen attached to the fiber surfaces thus

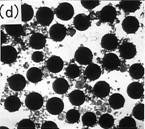

preventing fiber-to-fiber contact. Figure

6 shows

the optical micrographs of alumina continuous fiber reinforced aluminum alloy

composite fabricated by squeeze casting (fiber volume fraction; 40vol%).

|

|

Fig. 5 SEM image of a preform to

fabricate the hybrid composite. The alumina particles can be seen attached to

the alumina fiber surfaces.

|

(a) Composite without particles |

(b) Hybrid composite |

Fig. 6 Optical micrographs of alumina continuous fiber reinforced aluminum alloy

composite fabricated by squeeze casting (fiber volume fraction; 40vol%).

Flat surface

must be obtained to observe the microstructure. If a specimen is polished for

too long on the pad its surface may become rippled due to the difference of the

hardness between the ceramic reinforcement and metal matrix. Plating the

conductive materials such as carbon, copper or gold on the surface by PVD or

ion plating would be effective to observe the microstructure of the composite

because many of the ceramic reinforcements and inorganic binder retained on the

reinforcement are insulators.

Reaction between the reinforcements and the matrix is sometimes too

minor to be detected by the optical microscopy. Scanning and transmission

electron microscopy(SEM, TEM) or electron probe X-ray

microanalysis (EPMA) would be

effective in that case. Crystallographic information obtained by electron

diffraction.

A

large number of dislocations can also be seen in the matrix near the fiber in

the composite, as shown in Fig. 7.

The dislocations are probably formed by the thermal expansion mismatch between

the matrix and the fiber. It is reported that the incorporation of ceramic

fibers into the heat-treated alloy reduces the incubation time for the

nucleation of precipitates by the dislocation, leading to the achievement of

the peak hardness in a shorter time.

|

|

Fig. 7 TEM

photograph of a region near a fiber-matrix interface in the short alumina fiber reinforced aluminum alloy composite fabricated by squeeze

casting. Dislocation can be observed in the aluminum matrix near the fiber

(arrows).

Extracting the reinforcement from the

composite by acid or alkali is another method to observe the reinforcement in

the composite. Acid or alkali must be carefully selected so that they do not

attack the reinforcement. Figure 8 shows SEM image of the extracts from the alumina fiber reinforced

aluminum alloy composite by 30% nitric acid. No fiber damage or interfacial

reaction can be seen. You can see not only fibers but also eutectic silicon

which is originally contained in the aluminum alloy. Some eutectic silicon can

be seen near or on the fiber surface. This indicates that the eutectic silicon

tends to crystallize on the fiber surface and then grow near the fibers. If the

pronounced interfacial reaction occurred as shown in Fig. 1, the reaction

products would be seen in the extracts. In this case, it would be possible to

identify the product by X-ray diffractometry.

|

|

Fig. 8 SEM image of

the extracts from the alumina fiber reinforced

aluminum alloy composite by 30% nitric acid.

* This article is based on 乬K. Asano et al.: Trends of

composite casting technology and joining technology for castings in Japan丆International

Journal of Cast Metals Research Vol.21(2008),

No.1-4(p.219-225)乭.