Research Themes

Keywords:

metal matrix composite,

in-situ composite, casting, melting and solidification

process, cast iron, aluminum alloy, magnesium alloy

1.

Fabrication of

short potassium titanate fiber reinforced aluminum

alloy composite and its properties

– Development of new machinable aluminum alloy

composite –

The use

of aluminum alloys has increased in many industrial applications because the

reduction in the weight and size of the products, such as automobile parts, has

recently been promoted. These applications often require the improvement in the

strength, rigidity, heat resistance and wear resistance of the aluminum alloy.

To satisfy these requirements, the reinforcement of the aluminum alloy with

ceramic fibers or particles has been presented. The aluminum alloy composites

reinforced with the ceramic fibers or particles have been not only studied

fundamentally but also made by way of trial or put into practical use. However,

there is a concern about a decrease in machinability of the aluminum alloy by

reinforcing with ceramics, because ceramics are generally difficult to machine.

Therefore, it is very important to clarify the machinability of the composites.

To develop a machinable aluminum alloy composite

having low thermal expansion rate, we have noticed the potassium titanate as the reinforcement because it has low thermal

expansion and hardness. Although several investigations have been conducted on

the aluminum alloy composites reinforced with the potassium titanate

whisker, the whiskers are considered harmful to the respiratory organs. The

short potassium titanate fiber, having greater

diameter and length than the whisker, was developed to reduce this concern.

Based on these findings, we fabricated aluminum alloy composites reinforced

with the short potassium titanate fibers by squeeze casting, and clarified that the

thermal expansion coefficient of the composite was lower than that of the

aluminum alloy.

In

the present study, short potassium titanate fiber

reinforced aluminum alloy composites are fabricated, and the effects of the

fiber volume fraction in the composite and cutting conditions on the

machinability are clarified by measuring the cutting resistance and tool wear,

and observing the machined surface and chip forms.

丂

|

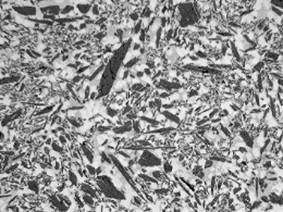

Optical micrograph of the composite (亊100丆dark phase: potassium titanate fiber) |

|

2.

Fabrication of

short alumina fiber reinforced aluminum alloy composite and its properties – Development of aluminum alloy composite

with heat and wear resistance –

Aluminum alloys have been used in many

industrial applications as the lightweight material instead of steel or cast

iron, because it is lightweight and its strength can be improved by alloying or

heat treatment. However, their use in parts that require heat resistance or

wear resistance is still limited because their high temperature strength and

wear resistance are insufficient. In order to improve these properties, the

reinforcement of the aluminum alloy with ceramic fibers has been presented. The

alumina fiber would be most suitable for improving the properties of the

aluminum alloy, because its high temperature strength and hardness are

superior. The alumina fiber-reinforced aluminum alloy composites have not only

been fundamentally studied but also made in trials or put into practical use.

From the viewpoint of the practical use of such composites, it is very

important to clarify their machinability. There is a concern about a decrease

in machinability of the aluminum alloy by reinforcing with alumina fibers,

because alumina is generally difficult to machine. However, the machinability

of the composite has not yet been sufficiently clarified. In addition, there

are many chemical compositions and crystal structures of alumina fibers, and

the properties of the fiber strongly depend on its composition or structure.

There are no reports regarding the effect of the properties of alumina fibers

on the machinability of a composite.

In the present study, short alumina fibers

having different properties are used as the reinforcements of the aluminum

alloy, and a fiber preform is infiltrated with the aluminum alloy melt by

squeeze casting in order to fabricate the composite. The effects of the fiber

reinforcement on the machinability of the aluminum alloy are then clarified.

丂

|

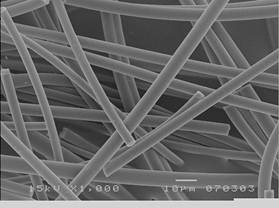

Scanning electron image of alumina fibers |

3.

Fabrication of

carbon fiber reinforced aluminum alloy composite and its properties – Development of aluminum alloy

composite with high thermal conductivity –

These

applications often require the improvement in the strength, rigidity, heat resistance

and wear resistance of the aluminum alloy. To satisfy these requirements, the

reinforcement of the aluminum alloy with ceramic fibers or particles has been

presented. In recent years, the performances of machines and electronic

equipment have been drastically improved. At the same time, these components

tend to be exposed to the severer environment. For example, high temperature

leads to an incorrect action or damage of the

equipment. It is important to release the heat from the components as soon as

possible. High thermal conductive materials are required to satisfy this.

Although aluminum is known as a metal with high thermal conductivity and low

density, higher thermal conductivity has been required recently to apply for

the machines

and electronic equipment

with high performance. Carbon fiber, which has a high thermal conductivity, is

one of the candidates. To our knowledge, however, it is not easy to obtain the

high thermal conductivity by the reinforcement with the carbon fibers.

Additionally, aluminum reacts with carbon at elevated temperature and leads to

the formation of aluminum carbide harmful to its properties. Needless to say,

it is very important to prevent from the reaction progressing.

The purpose of

this work is to solve these problems that obstruct the practical application of

the carbon fiber- reinforced aluminum alloy composite.

4.

Microstructure of

Niobium silicide based in situ composites – Development of future superalloy –

New

high temperature structural materials are required for the next generation of

advanced aircraft engines. Many intermetallic

compounds have been studied as candidate materials that could replace the

conventional nickel-based superalloys. Niobium silicide based in situ composites are

very promising candidates for future application in airfoils. While these in situ composites

exhibit excellent creep strength at elevated temperatures, they lack oxidation

resistance and suffer from poor fracture toughness at room temperature. From the viewpoint of the practical use of

these composites, we need to solve these drawbacks.

The

purpose of this work is to understand the effects of transition metal,

refractory metal and free electron metal additions on the microstructure of the

in situ composites based on Nb-18Si and the oxidation of these alloys.

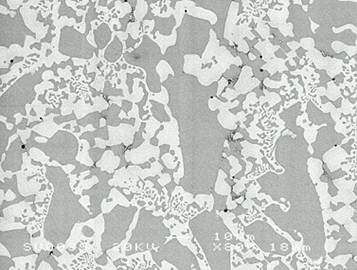

|

BEI image of the composite (dark

phase: niobium silicide) (bright phase: niobium solid solution) |

5.

Effect of tramp elements on microstructure of thin wall

spheroidal graphite cast iron

Cast iron has been produced in quantity as the castings for automobile parts and industrial

machines, because it has excellent castability, good

wear resistance and damping capacity. Recent years, reduction in weight and

size of the machine products has been promoted to reduce the energy

consumption, use of raw material and exhausting of greenhouse gas. This trend

leads to the promotion of thinning of the spheroidal graphite cast iron

castings. However, the cast iron melt in thin wall is exposed to the rapid

cooling, and the cementite (chill) tends to increase out in the matrix. The

chilling causes the decrease in the mechanical properties of the castings. For

the spheroidal graphite cast iron, it is reported that the increase in graphite

nodule in the matrix is effective for preventing the chilling without any heat

treatment. It is also reported that the addition of some tramp elements is

effective for increasing the graphite nodule count. However, the effect of these elements on

the graphite and matrix structure of the thin wall spheroidal graphite cast

iron

has not yet been sufficiently clarified.

In this study, the effects of tramp elements on the

microstructure of thin wall spheroidal graphite cast iron are examined.

Some of researches shown above are collaborated

with some companies or carried out by grants-in-aid.